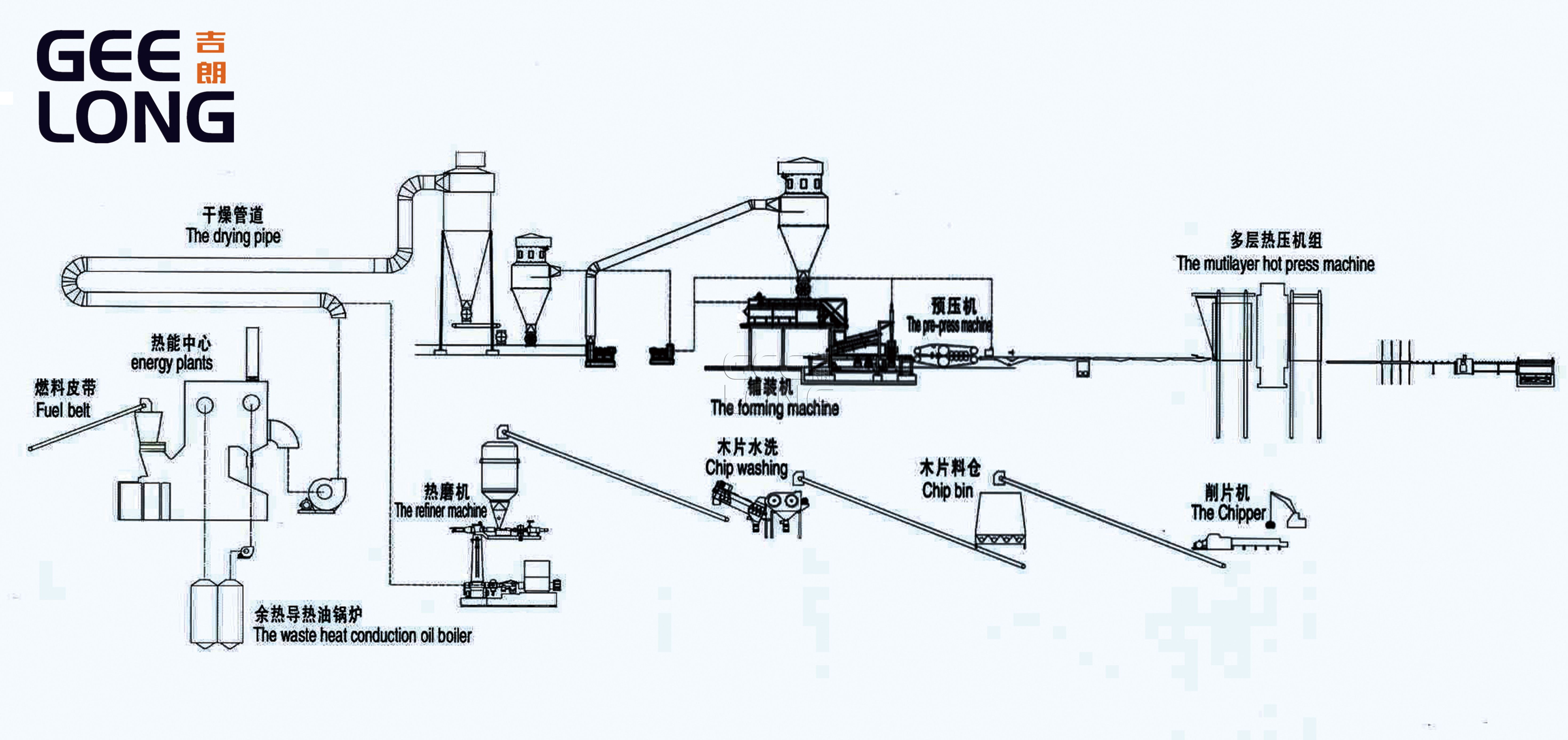

GEELONG is proessional MDF machine manufacturer. we can provide the whole set MDF machine.

Like the chipper machine, the refiner machine, the drying machine, the forming machine, the pre-press machine, the multilayer hot press machine, the sanding machine and other MDF machine.

We don't only produce the MDF machine, we also design the whole MDF machine layout.

Feel free to contact us to get more details.

Description of Technical Process

The medium density fiberboard is processed (through sections of material preparation, fiberpreparation, regulating and supplying glue, forming and hot pressing, post-processing, and sanding) to be 450-880kg/cm3 from the raw materials of wood fiber or orther plant fiber. And the raw materials can be wood, brushwood, and the processing residues of wood.

Material preparation section

After the raw materials are sawn into wood pieces of certain sizes by a wood chipper and stored in a material warehouse, impurities, such as fines, earth, and sand, are removed from the wood pieces through screening.

Fiber preparation section

Feed the wood pieces into the boiling apparatus evenly to cook and soften through squeezing and dewatering after transferring them into the defiberator pre-heating bins/humidifying bins by the transferring equipment in order to separate the fibers easily. The cooked wood pieces will be separated to fibers under the forces of heat and machine. Then mix the wet fibers and heated dry medias, and keep the fibers suspending in the dry medias under the high speed force of the high-pressure air flow,and the moisture in the fibers will be taken away by the dry media. Afterwards, the fiber will drop under the force of cyclone separator onto the reversible belt conveyor to be transferred to the pavement bins for temporary storing.

Mat-forming and hot-pressing section

The dried fibers are transferred into the paver metering bin by the pneumatic system, and the paving rolls of the mechanic vacuum paverpaves the fibers onto the circular conveyor. And the air will be sucked away by the mesh belts, under which there is vacuum case forming negative pressure, as while, the fibers are sucked on the mesh belt and form slabs gradually. In the next moment, the fluffy slabs will be compacted by the pre-press machine, and be sawed vertically and longitudinally to lengths required, and then the slabs will be transferred to the loader by the synchronous conveyor, speed-up conveyor, storing-board conveyor and extensible conveyor successively. After being loaded by the loader, the small machine in the loader will transfer the slabs together with the cantilever belt into the hot press machine. During this transferring process, the shovel at the front of the conveyor belt push the compacted slabs out, and the rough boards will enter the unloader as well as slabs get to the preset position when the small machine arrives at the termination. Then the small machine draws back as the be!t revolve forward. The revolving speed of the belt is equal to the back speed of the small machine, so that the slabs are relatively static and stay on the hot press. The slabs will be formed to specified thickness under the temperature and pressure of the thermal compressor, and the inside glues will solidify. At last boards of certain strength will be made. Then the boards will be unloaded onto the carrier by the unloader, and unloaded transferred to the next process by the discharge machine gradually when the suspension coop goes down layer by layer.

Finishing and sanding section

The thermal-compressed slabs will be cooled through turning over and transferred to the vertical and horizontal sawing machine by the roller conveyor to be sawed into medium density fiberboard in required sizes, and at last, to be separated, stacked, packed and transferred to the warehouse after sanding.